- Al Quoz - Al Quoz Ind Area 4 - Dubai

- info@bluestarllcdubai.com

Cyclone Separator

- Home

- Cyclone Separator

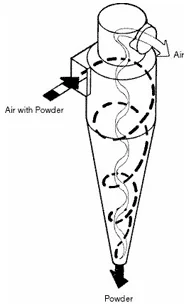

Principle of Cyclone Separator

Cyclone separators operate on a cyclonic separation principle. Dust-laden air is blown into or drawn through the cyclone and forced to move in a circular motion. The airstream spirals downward to the base of the unit as centrifugal forces move the heavier dust particles to the side walls. The motion continues spiraling downward to the base of the unit. The dust then falls out and the air reverses up through the inner tube and out the top.

Cyclonic separation efficiency is determined by the cyclone geometrical parameters, the density of the solids, and the rotational velocity of the air stream. It is essential that the geometry of each internal component be designed to promote a smooth transition in maintaining laminar flow characteristics.

Cyclone separators utilize gravity and a vortex to remove particulates from gaseous streams. Industrial cyclones are used in pollution control applications most commonly as a first stage, lower cost method for removing larger particulate matter (PM) from effluent gas streams. Because cyclone separators do not incorporate filter media or moving parts, the pressure drop (therefore, operating costs) and maintenance requirements tend to be low. They can also be constructed to withstand harsh operating conditions, and since separation in cyclones is a dry process, the equipment is less prone to moisture corrosion.

Cyclone Separator Advantages

- Stable pressure drop for a given gas flow

- Constant efficiency for a given particulate condition

- No moving parts; no replaceable filters

- Ability to handle extremely high dust concentration

- High temperature capability

- Coarse particle size distribution

- Higher product specific gravity

- Lower gas density

- A decrease in cyclone diameter (two smaller cyclones in parallel will have a higher efficiency than one larger cyclone with an equal pressure drop